Automatic nutritional powder breakfast cereal making machine nutrition flour processing line baby food making machine

Share

Dimension(m): 1.1×0.8×1.4

Motor Power: 4KW

Speed: 400rpm

Throughput: 30kg per loading (5-6 minutes per loading)

Functions:Mix powder raw material with water

Features:

1. stainless steel material(1.5mm).

2. new handle-opened design of discharge holes,no material leak

3.High speed can mix material better than other slow mixer..

Screw Conveyor

Dimension(m): 3.2×0.6×0.7

Motor Power: 1.1KW

Screw speed: 300rpm

convey height range:1.5~2.5M

barrel diameter: Φ141mm

Function:

Power material can be conveyed in the stainless steel roller to the feed machine of extruder without leaking, dust and pollution;

Twin-screw Extruder

Dimension(m): 2.6×1.0×1.3

Total power: 37kwMain Motor Power:22KW

Feeder motor:0.75kw

Cutting motor: 1.5kw

Heating power:10kw

Extruder diameter:Φ65 mm

Function:

Extrude and cook raw material into different size and shapes

Features:

Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.. The barrel also use good material, hardness is 55HRC.

The gear box has forced lubrication system.

All motors can be adjusted the speed by Inverter.

The Extruder can change different molds to produce different Shapes product.

Sifter

Dimension(m): 1.6×0.7×0.5

Motor Power: 0.4KW

Functions:

To vibrate the bread crumbs to remove the powder mixed in the bread crumbs.

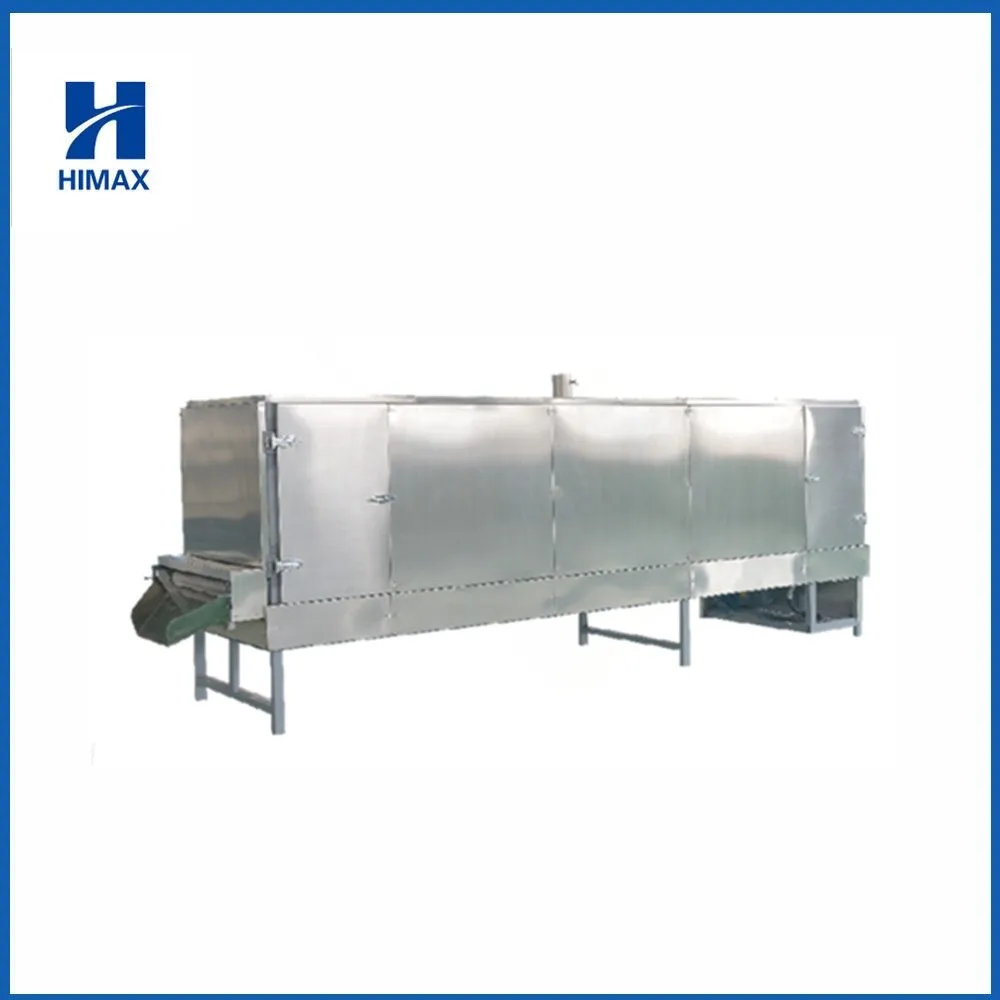

Dryer

Dimension(m): 5.4×1.3×1.8

Heating Power:27kw

Motor power:0.75kw

Belt speed:0.1-10M/minute

Temperature: 20-200℃

Function:There are Three layers inside,each layer is 5 meters long, it can save space and energy. Electricity heating,used to bake and dry food.

Features:

The net belt running speed can be controlled by Inverter, to change the food drying time in the dryer.

Heating adopts the electric heat tube.

It has automatic temperature Control system.

The belt and the cover are all stainless steel.

Product Introduction

1).Baby food rice powder making machine adopt the technology of occident equipments.

2).They have many characteristics such as high automation, good stability, easy operation, large output and short time etc. what is more, it has improved the technology which avoid some of the traditional abuse.It can process various materials, widely applied in many industries: baby rice powder, sesame paste, and nut paste food etc.

3).This nutritional rice powder processing line is a new generation and high efficiency line.

|

Model

|

HM65

|

HM70

|

HM85

|

|

Installed Power

|

77kw

|

108kw

|

150kw

|

|

Power Consumption

|

50kw

|

75kw

|

100kw

|

|

Capacity

|

120-150kg/h

|

220-260kg/h

|

400-500kg/h

|

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.