Automatic Raw Cashew Nut Production Line Cashew Nuts Processing Machine Cashew peeling drying cleaning machine

Share

Automatic Raw Cashew Nut Production Line Cashew Nuts Processing Machine Cashew peeling drying cleaning machine

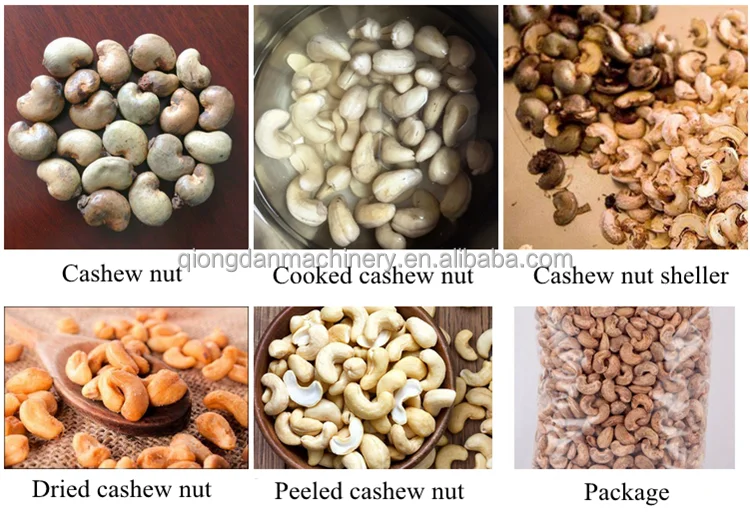

Description of cashew nut processing line

The cashew nut processing line is suitable for the production of various sizes’ cashew nuts. The shelling and peeling machine adopt a special blade design, which will not damage the cashew nuts.

The production line has the characteristics of high production efficiency, small footprint, convenient operation, and maintenance.

The small cashew nut shelling line not only has one output, but it can also be customized according to the customer’s output.

The above machine equipment scheme is our regular cashew nut processing machine. If you have different processes to process cashew nuts, we can equip the machine according to your requirements.

Cashew nut processing machine flow chart:

Cashew nut processing equipment mainly includes cashew cleaning machine, grading machine, cooking machine, peeling machine, shell and kernel separator, drying machine, peeling machine, roasting machine, packing machine.

Parameter of cashew nut processing line

| Name | Power | Capacity | Machine size | Weight |

| Cashew cleaning machine | 1.1kw | 500kg/h | 1.58*0.85*0.8m | 180kg |

| Cashew nut grading machine | 1.1kw | 500kg/h | 3.6*0.9*1.6m | 450kg |

| Cashew cooking machine | 18kw | 200kg/h | 1.5*0.6*1.55m | 150kg |

| Cashew nut shelling machine | 3kw | 240kg/h | 1.45*1.33*1.55m | 700kg |

| Cashew shell kernel separator | 2.2kw | 400kg/h | 1.25*0.85*1.85m | 320kg |

| Cashew kernel peeling machine | 0.1kw | 200kg/h | 0.71*0.69*1.38m | 110kg |

| Cashew nut roaster | 2.2kw | 200kg/h | 3*2.2*1.7m | 500kg |

Cashew cleaning machine

The cashew nut cleaning machine is a brush cleaning machine that can remove impurities on the surface of the cashew nut. There are 9 brushes evenly distributed inside the machine, and the brushes are in full contact with the cashew nuts. Therefore, the machine can completely remove impurities on the surface of the cashew nuts. The machine is made of all 304 stainless steel, and it has movable casters for easy movement.

Cashew nuts grading machine

A grading machine can be used to grade cashews before they are shelled. Different grades of cashews have slightly different prices. In this step, it can distinguish different grades’ cashew nuts to facilitate subsequent processing. The cashew nut processing machine is suitable for grading cashew nuts of different sizes, and the machine can distinguish 3-5 grades according to customer requirements.

Cashew nut cooking machine

The cashew nuts have a hard shell. During processing cashews, the cashews need to be steamed and then peeled. Through the cashew nut cooking machine to steam cashew nuts, it will create a space between the cashew nut shell and the kernel. This way can increase the efficiency of cashew nut shelling. The cashew machine manufacturer provides you with electric and gas heating machines. It has different specifications and output.

| Model | QD-ZZX-600 |

| Voltage | 220v |

| Power | 0.75kw |

| Capacity | 600kg/h |

| Weight | 420kg |

Cashew nut sheller machine

There are three types of cashew shellers: Automatic sheller, semi-automatic cracker, and manual sheller. They can produce cashew nuts of different scales and apply them to different regions.

An automatic cashew nut shelling machine is designed to break the shells of cashew nuts. It is fully automatic and easy to operate. Factories could shell 6, 8, 10, 12, and more cashew nuts at one time and it causes the least damages to cashew kernels. The automatic sheller is appropriate to use in a large-scale production line.

A semi-automatic cashew cracking machine could shell 6 cashew nuts at one time. Workers need to put cashew nuts into the holes and step pedals to crack shells. The machine should be careful to operate for it requires more human participation. It is more suitable to match with a semi-automatic production line.

And for manual cashew sheller, workers put one cashew nut into the hole, step pedal to shell nuts. This is suitable for some areas with lower labor costs for they could hire more workers to produce nuts.

Cashew shell kernel separator machine

In order to increase production efficiency and reduce manual contact, it generally use a shell and kernel separator to separate cashew nut shells and kernels. The shell and kernel separator uses the principle of different weights of shell and kernel to distinguish the two. It is widely used to distinguish the shell and kernel of nuts after shelling. Therefore, this cashew processing machine usually equips with a nut shelling machine.

| Model | QD-KRFL-500 |

| Voltage | 380v |

| Power | 1.1kw |

| Capacity | 500kg/h |

| Machine size | 1.9*0.8*1.4m |

| Weight | 140kg |

Cashew Drying Machine (Optional)

This dryer is used to dry cashew kernels so it is easier to blow off the skins in the following peeling machine. The size could be made to match with the customer’s output. It could use electricity and gas as heating sources. And the machine could also dry other nuts and food. Customers could also dry cashew kernels naturally.

| Model | QD-HKX-1.2 | QD-HKX-1.6 | QD-HKX-2 |

| Power | 11.4kw | 14.6kw | 19.7kw |

| Capacity | 60-160kg/h | 85-220kg/h | 100-260kg/h |

| Drying time | 0.2-1.2h | 0.2-1.2h | 0.2-1.2h |

| Bandwidth | 1.2m | 1.6m | 2m |

| Dry section length | 8m | 8m | 8m |

| Paving thickness | 10-80mm | 10-80mm | 10-80mm |

| Temperature | 50-140℃ | 50-140℃ | 50-140℃ |

| Steam pressure | 0.2-0.8Mpa | 0.2-0.8Mpa | 0.2-0.8Mpa |

| Steam consumption | 120-300kg/h | 150-400kg/h | 180-500kg/h |

| Machine size | 9.56*1.49*2.3m | 9.56*1.9*2.4m | 9.56*2.32*2.5m |

| Weight | 4500kg | 5300kg | 6200kg |

Cashew nut peeling machine

The cashew peeling machine uses the pneumatic principle to automatically peel the cashew nut. The machine can apply for peeling dried cashew nuts, and the peeling rate is over 98%. It makes up for the defect that the peeling machine can only be applied to wet cashews. It increases the production efficiency of cashews and reduces the workload of manual operations.

Cashew Kernel Classifying Machine

The cashew kernel size sorter is specially designed for grading peeled cashew kernels. And the machine usually includes 3 grades, which could be tailor-made according to the requirements of customers. The grader includes a hopper, three layers of rollers, and outlets. With high output and less damage to the shape, this size sorter could be a perfect choice for plants in the processing line.

Cashew nut roaster

The roaster machine can use electricity, gas, and other heating methods, and it is suitable for roasting all kinds of nuts. In the small cashew nut line, the 200kg/h roaster machine has two barrels to roast cashew nuts. It will not damage cashew nuts when roasting. And the machine is an intelligent control machine, it can adjust the baking temperature and time.

Cashew nut Packing machine

Pack the processed cashew kernels.

Pictures of cashew production line

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.