Diaphragm Micro Vacuum Pump Mini Air Pump

Share

Diaphragm Micro Vacuum Pump Mini Air Pump

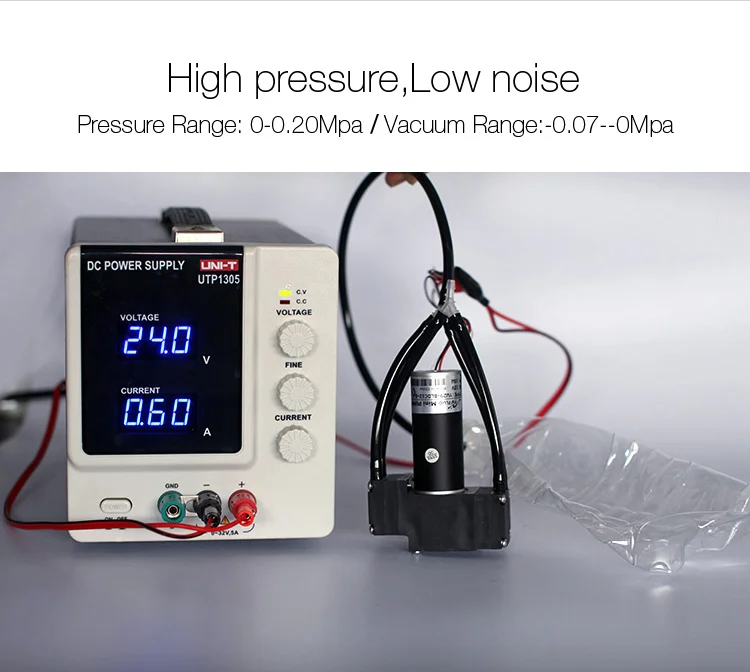

YW29Micro Diaphragm Pumps are a series of brush and brushless DC motor driven pumps which are customized to meet the specific performance requirements.The innovative compact designs adopt leading technology.so the pumps will operate more efficient.

YW29 can be used for vacuum, pressure or alternating

vacuum and pressure operations.

YW29 is ideal for compact, high flow, wide pressure ranges, long life and low noise applications.

Typical Applications

• medical facility

•environmental protection

• Chemical Technology

• laboratory applications

• food engineering

• home applications

Features

• YW29series pump with our unique brushless dc

motor design, Set new standards for maintenance-free performance,

• YW29maximize flexibility by providing multiple installation options,

• Our 100% oil-free and grease-free diaphragm pump and compressor designs maintain the purity of the

system and pass the international certified.

Product Specifications

| Physical Performance |

Electrical performance |

Pneumatic performance |

| Operating Environment1 : |

Motor Type: |

Head Configuration: |

| 0-40℃ |

brushless motor, brush motor | Dual |

| Storage Environment: |

Nominal Motor Voltages4: | Maximum Flow Rate: |

| -20-100℃ |

12VBLDC,DC Other voltage can be customized. | 12L/min |

| Media: |

Current Range5: | Pressure Range: |

| Nonreactive gas |

0.68- 1.5A | 0-0.20Mpa |

| Humidity: |

Kitting Materials | Vacuum Range: |

| Less than 80% |

Diaphragm: | -0.07--0Mpa |

| Noise Level2: |

EPDM | Filtration: |

| 70dB |

Valves: |

/ |

| Pump Assembly Rated Life3 : | EPDM | Free Flow Efficiency: |

| BLDC 6000h DC1000h |

Pump Head: | / |

| Weight: |

PPS | |

| 288.4g/pcs |

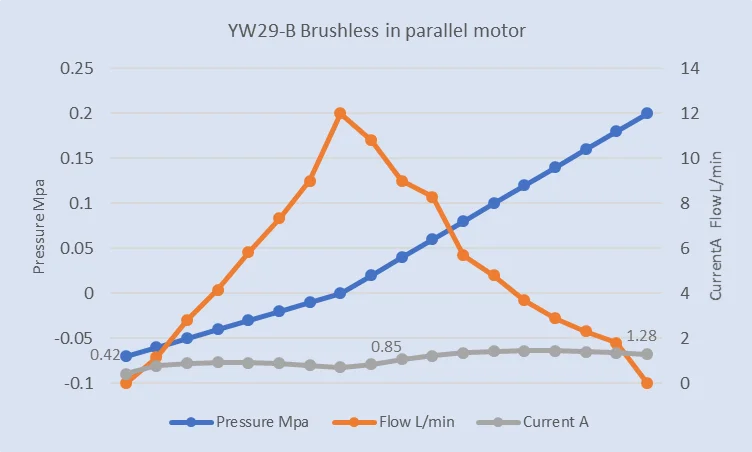

Performance specifications

The figure above represents a performance example of the YW29 series pump .Performance will depend on atmospheric pressure and medium temperature.The curve represents the standard pump configuration.Pump configurations can be customized for higher or lower flow according to specific customer requirements.

If have any requirements, please contact Changzhou Yuanwang Fluid Technology Co., LTD.

Size and Selection

| Item |

Efficiency |

Life span |

Cost |

Noise |

| YW29-B in Parallel |

Best-Up to 75% motor efficiency at high power levels |

Good -6000 hrs |

Best |

Good |

| YW29-B in Series |

Better-Up to 60% motor efficiency at low loads |

Good - 6000 hrs |

Good |

Electrical Integration and Motor Control

| Item |

Flow |

Pressure |

Vacuum degree |

Motor Type |

Voltage |

Noise level |

| YW29-B in Parallel |

12L/min |

0.20Mpa |

-0.07Mpa |

BLDC/DC |

12V |

70dB |

| YW29-B in series |

8.3L/min |

0.20Mpa |

-0.085Mpa |

BLDC/DC |

12V |

70dB |

Brush Motor

| Two(+,-) |

|

| specification |

Thickness0.5mm,width2.8mm,Height6.2mm |

Brushless Motor Control Options

| Red (+), Black (-) |

|

| 3 Wire (Speed Control) |

Red (+), Black (-), White (PWM) or Yellow (Analog) |

| 4 Wire (Speed Control & Feedback) |

Red (+), Black (-), White (PWM) or Yellow (Analog),Blue(tachometer) |

| Wire specification |

22AWG, Insulation OD 0.051 inch (1.30 mm), 20” (508 mm) Wire Leads |

Other Motor Control Considerations

The drive electronics for the BLDC motors are integrated into the motor itself, all that needed is a power supply with the sufficient voltage and current.

Key Things to Remember

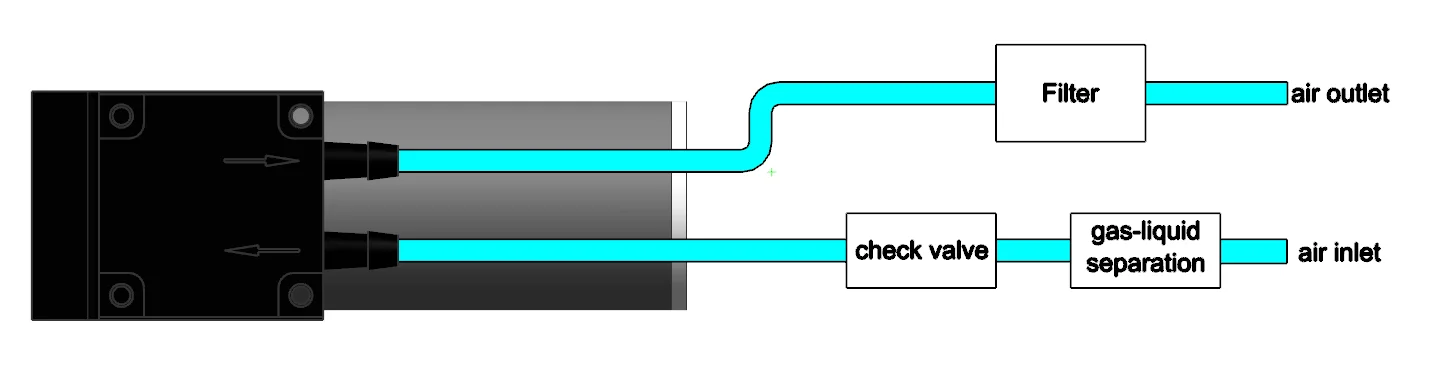

The pump is not a pressure holding device. An external check valve is recommended, if there is a pressure holding requirement.

Pump orientation does not affect performance or life.

Pulse Width Modulation (PWM)

Pulse-width modulation is a commonly used technique for controlling DC motors.

1.The average value of the voltage fed to the motor is controlled by turning a switch between the voltage supply and the motor on-and-off at a fast pace. The longer the switch is on compared to the off time, the higher the power supplied to the motor.

2.The PWM switching frequency varies for different types of devices, and is selected based on how it affects the device. For example, Some applications require a faster switching frequency to reduce the noise or electrical noise that is being heard.

3.The term duty cycle describes the ratio of on-time to the period (one complete on-and-off cycle). Duty cycle is normally expressed as a percentage of on-time, 100% being full-power and 50% being half-power.

4.The advantage of PWM is the reduction of power-loss due to switching versus other control methods. We recommends controlling the pump using 15kHz - 20 kHz frequency range.

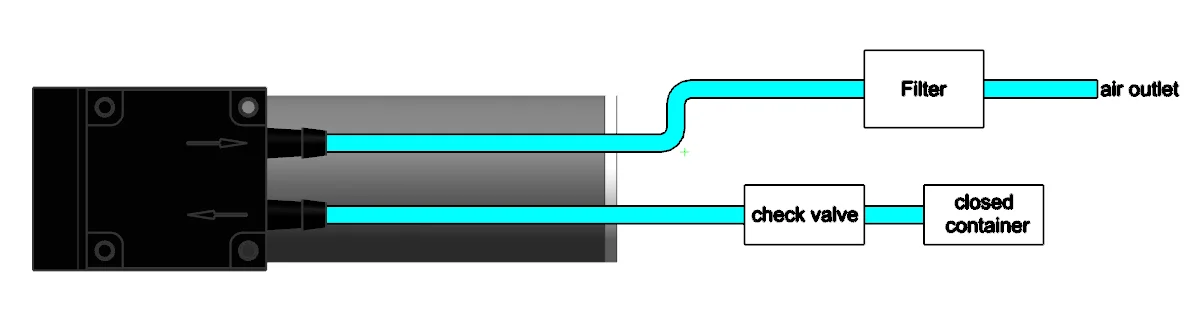

Typical Flow Diagram

Gas transport case

Vacuum case

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.