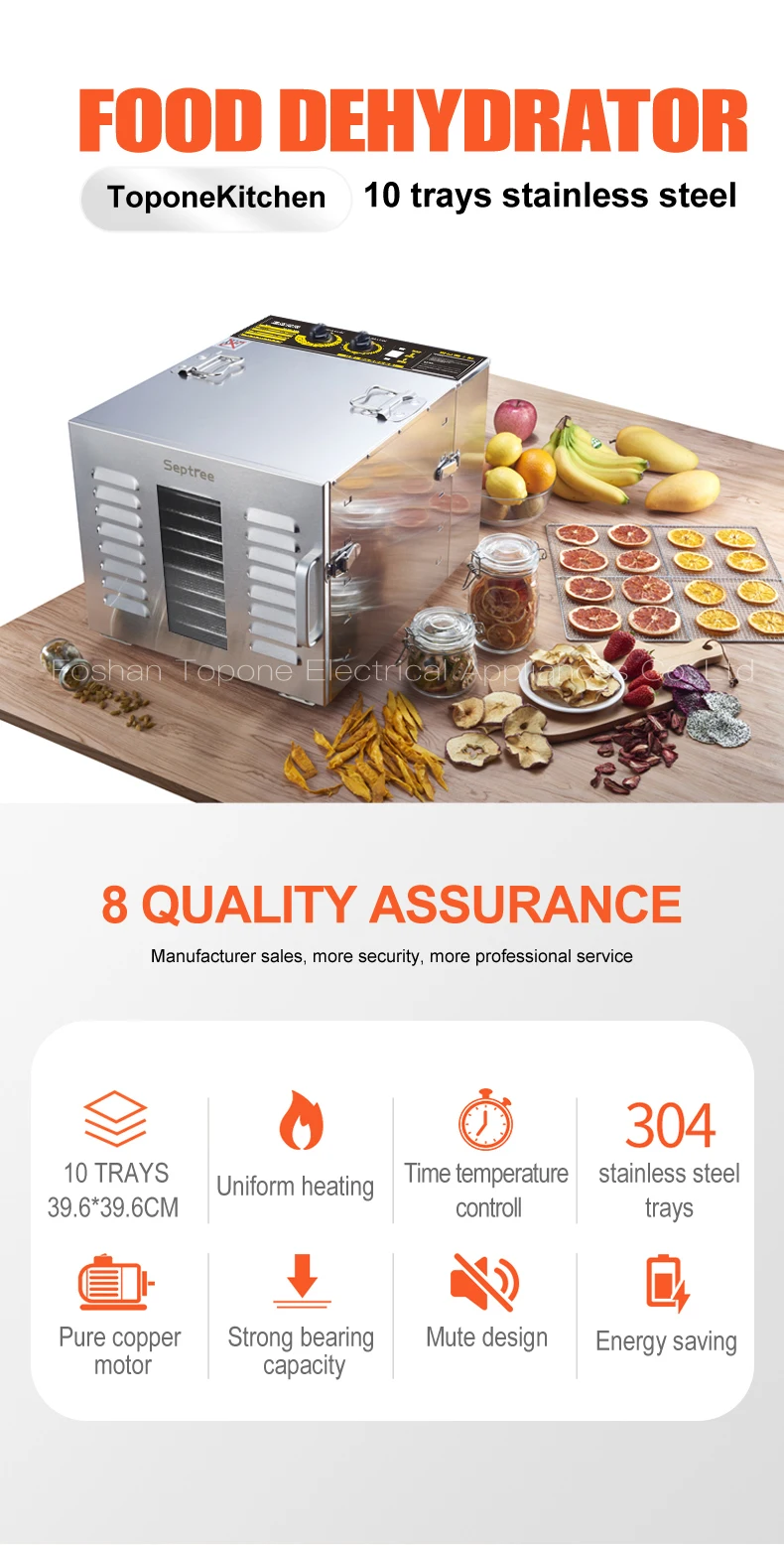

mini home dry fruit machine 10 layers food dehydrator for home use

Share

|

Item NO.

|

ST-01

|

|

Product Dimension (W X D X H )

|

560X420X435mm

|

|

wooden case Dimension (W X D X H )

|

600 X480 X450mm

|

|

Rack Size(L X W)

|

396x396mm

|

|

Rack Grid Spacing

|

8mm

|

|

Rack Gap

|

35mm

|

|

Total Trays

|

10trays

|

|

N.W (KGS)

|

16kgs

|

|

G.W (KGS)

|

18.5kgs

|

|

Product Material

|

Food grade 304 stainless steel racks;

201 stainless steel housing, lifting handles, latches;

Stainless steel with tempered glass window door;Aluminum alloy door handle;

Control panel with PVC finish and PF knobs

|

|

Power

|

1000W

|

|

Voltage / Frequency

|

220V/50hz(Conventional standard), 110V/60hz(Special-make, MOQ:1X20GP, extra cost USD 14/unit)

|

|

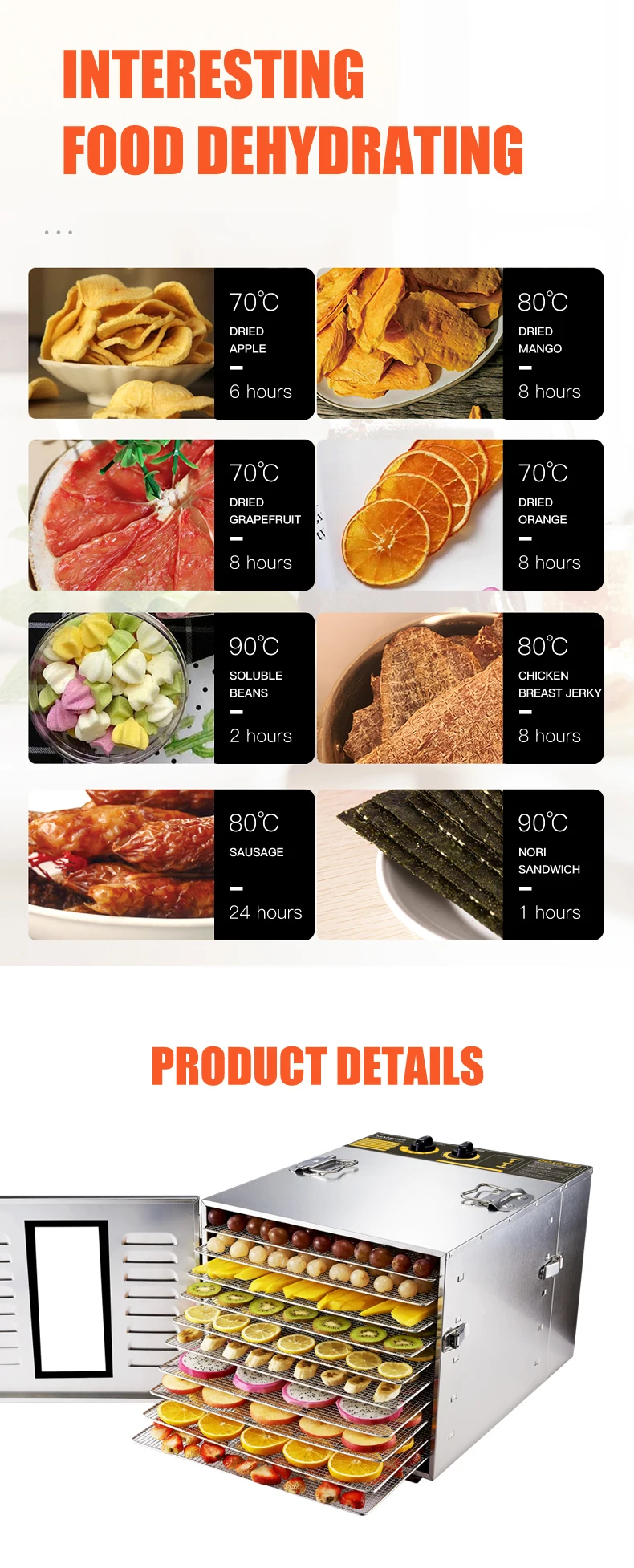

Temperature Ranges

|

40~90℃ (104~194℉)

|

|

Max. Timing

|

15hrs

|

|

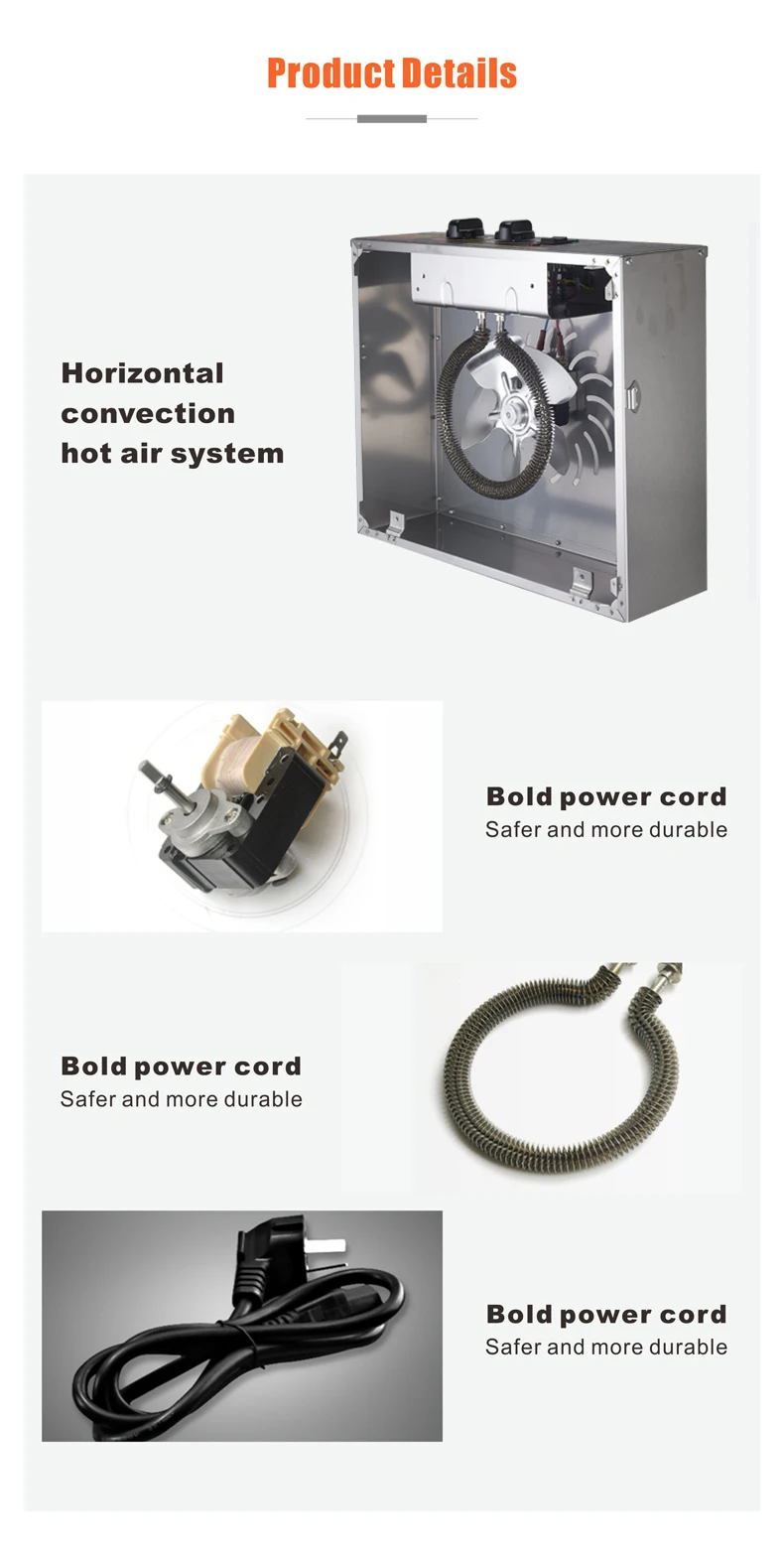

Noise Level

|

45-50dB

|

|

Capacity

|

69L

|

|

Warranty

|

1 year warranty / Provide techinicial support according to specific issues; / Provide FOC vulnerable parts

|

|

Packages

|

EPE cushion

High strength corrugated carton

B/W printing manual

|

|

Notes

|

1. Other special requirement shall be added to related cost

2.MOQ: 20GP container, can mix models. Extra sample fee will pay back after a 20GP.

3. Lead Time: For first order 35 days, and the repeated order 30 days after all OEM artworks confirmed.

4. Payment Term: T/T 30% deposit, the balance shall be paid one week

before shipment.

5. Certs: CCC, CE, ROHS, LVD, EMC

|

ODM project process

2.factory quoting: quotation is passed by customer and factory provide die design.

3.making prototype: within 5-7days, provide the 1:1 mock-up

4.confirmation of prototype: customer confirm the 1:1 mock-up after several adjustment

5.Opening mould. Produce the mould according to the confirmation of 1:1 mock-up,takes around 1-2months

6.testing mould. Try the mould repeatedly and make sure there is no flaws on finished products.

7.Trial production. Small mass production after passing the mould testing and do fully product test

8.Mass production. Start mass production after passing the trial production, and customer pay the deposit.

9.Inpection&delivery. Delivery within 4 weeks, customer arrange the balance payment.

Our company has perfect equipment and high-quality technical team, can customize products according to customer requirements.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.